Restore and Preserve EPDM, Thermoplastic, Thermoset, and Other Membranes

- Reduces membrane shrinkage, and chalking

- Multiple chemistry options (Acrylic, Polyurethane, OneStep)

- Reduces stress on seams, flashing, and penetrations

- Lowers energy costs

- Adhesion promoting primers used as needed

Membranes can become brittle, shrink and pull away from curbs, separate seams.

By being proactive and restoring a single-ply membrane before it is too late, allows you to avoid unnecessary and costly tear offs, reduce future maintenance costs, decrease heat transfer into buildings and therefore, increasing the ROI and life cycle cost of the roof.

Before & After Photos

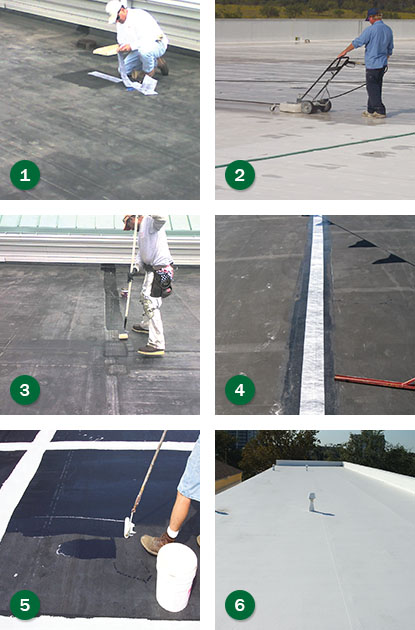

Process

1. Prepare. Address all problem areas. Identify any and all wet insulation. Repair and replace with like materials to make watertight before coating.

2. Power wash, removing dirt and debris.

3. Prime (if necessary) seams, preparing for Fabric Faced Butyl Tape.

4. Apply Fabric Faced Butyl Tape to all seams. The tape needs to be coated prior to base and top coat applications.

5. Prime (if necessary) entire field of roof with Single-Ply Primer topromote adhesion as needed. Primer needs to be coated at the same day.

6. Preserve. As the final layer of protection, apply 2 coats of Acrylic 1000 Plus/ Acrylic SW or Polyurethane 300 Finish Coat. OR 1 coat of OneStep after Fabric Faced Butyl Tape. It provides a weather resistant, seamless sacrificial barrier that will significantly reduce the harmful effects and damage caused by UV rays.

Benefits

- Reduce energy costs

- Slow the aging process

- Decrease future maintenance cost

- Change the life cycle of the roof